Do your BBs roll out of your inner barrels when your airsoft gas blow back sidearms are tilted downwards? Do your bbs land at varying range despite a full charge of gas? Are your groupings consistently wider than five inches within thirty feet? If you are experiencing any of these, your airsoft sidearm may need fixing.

Background

Here I have a WE-Tech F226. When I first saw the YouTube video demo shared by the company I was excited and pre-ordered one at my local airsoft shop. At the time I wasn’t too keen on purchasing a Marui variant and having to buy a metal kit to prevent slide crack as green gas is the more common power source in my area.

I also wanted something different from the existing KJW offerings and the kick demonstrated in the preproduction video by WE-Tech looked promising.

Problems

Fast forward to today my WE-Tech F226 didn’t see much use, at least that used to be the case. Out of the box the airsoft pistol had accuracy issues and the plastic BBs constantly rolled out of the barrel unless I set the hop-up settings to the max. The poor consistency and unpredictable nature of the piece also made it unreliable for skirmishing.

Analysis

Initially I tried swapping in an aftermarket hop-up bucking to remedy the problem, but that didn’t solve anything. Finally, I narrowed down the problem and traced the root cause back to the hop up arm’s length and travel. Compared to a proper performing airsoft gas blow back handgun the arm on my WE-Tech F226 failed to apply pressure on the bucking at the lowest setting on the dial. Adjusting the dial all the way to the max, the arm also fails to apply enough pressure on the bucking for consistent performance.

The Fix

The solution to this problem is to find ways to bring the arm closer to the bucking and increase the travel along the dial. By shortening the distance between the arm and bucking we are able to apply what I’d like to call pre-hop to the bucking which will prevent any BBs unexpectedly rolling out of the barrel. Likewise, the dial needs to provide consistent pull on the arm for consistent effect. For a video version of the comparison you can click this link.

Continuing, I purchased a Kuan Ju Works (KJW) KP-01 replacement hop chamber in hopes to transplant the whole chamber outright. Unfortunately, there were some fitment issues and before I could go any further, one of the body screws snapped at the head when I was trying to thread the slots. This prevented me from going further with a full transplant.

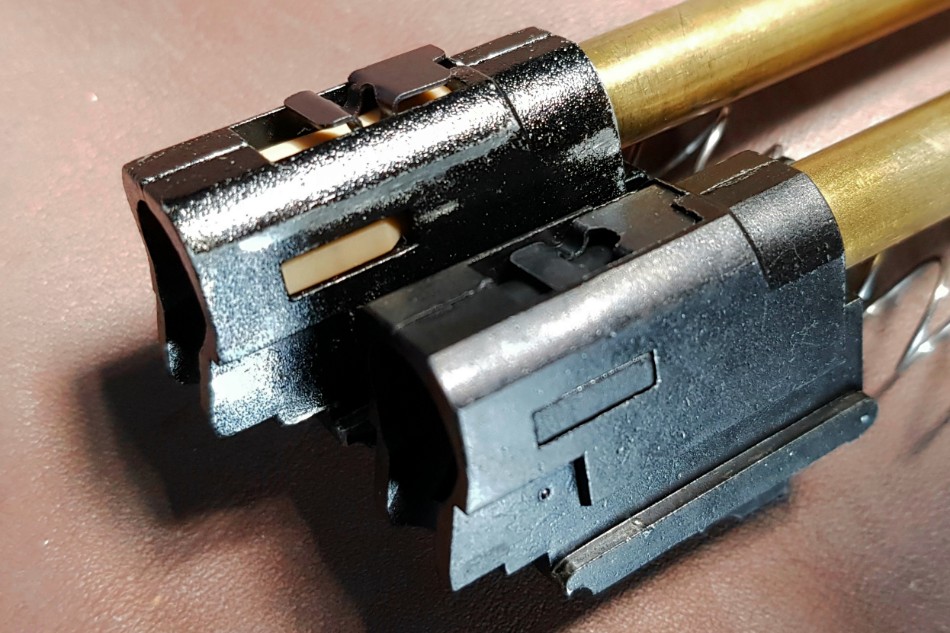

Luckily I found that the arm would transfer fine. Comparing the two arms from each hop unit it can be observed that the WE-Tech arm arches slightly higher than that of the KJW. This is where most of the height problem is coming from and thankfully the KJW replacement drops right in to fix it.

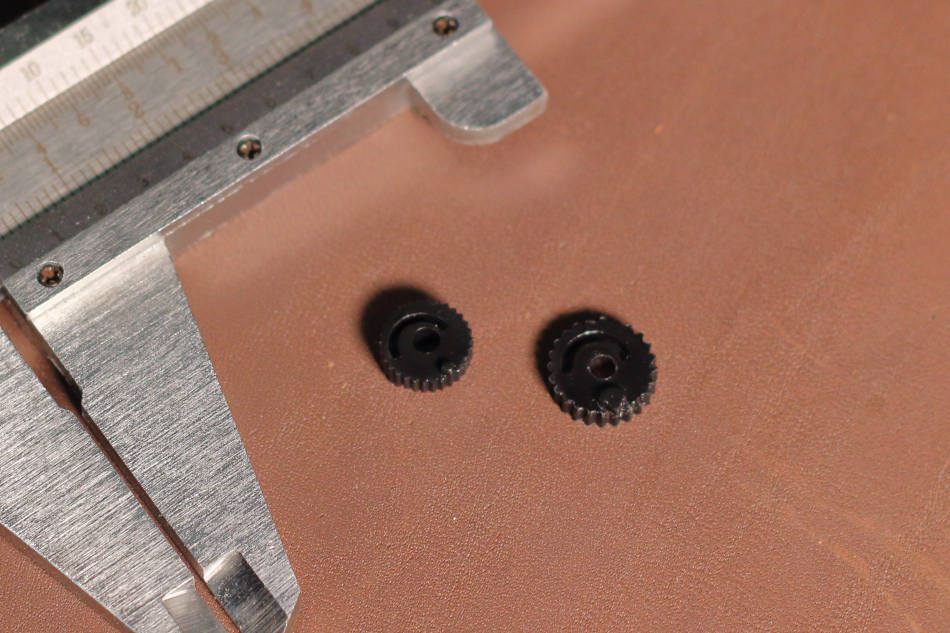

Next up on the list of things to fix that I found included the wheel adjuster. The hop wheel has a groove or channel that the hop arm rides along to gradually pull the arm down against the hop bucking. When looking at the WE-Tech and KJW wheel side by side I noticed that the rate at which the groove runs towards the center to pull the arm is higher on the KJW version found on the left than that of the WE-Tech’s on the right.

This explains why there wasn’t much change in the hop arm’s position in the initial half of the F226’s hop settings. The groove had not changed slope much until past the half way mark. Swapping this out for the KJW one would be recommended as the slope is more progressive, and luckily this a drop in replacement as well.

Findings

And that’s it! After swapping those two parts out, the issue with rolling BB’s and inconsistent performance should be resolved. For those interested, I also published a video comparing the groupings of my WE-Tech F226 before and after the repair. The shoot-out also included a stock Marui P226 for comparison.

The Marui P226 ended up shooting marginally better than the WE-Tech F226 with the fix applied. However, I attribute this minor difference to the plastic slide and snappy recoil which made target reacquesition easier compared to the WE-Tech F226’s more brutish recoil that caused my wrists to wobble each time the slide returned to battery.

Conclusion

If you are having trouble with your airsoft gas blow back pistol and are experiencing any of the symptoms I’ve described earlier like BB’s rolling out of the barrel and erratic performance, try this fix out.

I was pleasantly surprised to see the cheaper WE-Tech F226 improve in performance considerably after the repair was done. There are still reasons to purchase and build upon a more expensive Marui platform such as aftermarket parts compatibility and ease of customization, but if you’re looking for a beater sidearm an all metal bargain like the WE-Tech F226 does a good job without breaking the bank, assuming the kinks are fleshed out.

– J4